CNC is the acronym for a type of machinery that is heavily involved in everyday life. Although not directly, computer numerical control machines (CNC) use a specific technology that effectively engraves, cuts, shapes, and even melts certain materials. This technology is super effective, super convenient, and thoroughly accurate.

The technology is known as G-code. G-code was a revolutionary computer language that gave birth to these contraptions. We use products from CNC machines almost daily, making them one of the most important aspects of our society.

There are various CNC machines out there that range in functionality and usability. In this article, we will try and tell you all there is to know about the most common types of CNC machines. So, without further ado, let’s start.

1. Milling Machine

Milling machines are, by nature, mechanical, meaning that it takes a person to manually operate it. However, they’ve recently been paired with the G-code technology that allows a person to operate by giving it instructions through a computer.

This completely revolutionized their usage, by effectively removing all the mechanical parts such as the Digital Read Out electronics and handwheel, and replace it will the essentials needed to operate such mechanical equipment through external means.

Milling machines are some of the most versatile CNC’s out there, with their primary use being to flatten surfaces. Other uses include producing irregular surfaces, drilling, and cutting.

2. Lathes

These mechanical contrivance are used almost in every industry that needs creating specific shapes for a specific job. Mechanical engineers extensively study lathes, and every student must be well versed in how to handle one.

The main use of lathes is for turning, forming, taper turning, parting off, chamfering, counterboring, reaming, drilling, boring, grooving, knurling, and more; making it one of the most versatile machineries out there. It performs all of these operations through external tools that we apply to the machine, making it more effective at its job.

There are three types of lathes out there. Those include the engine, the turret, and the special purpose lathe.

3. Router

Onto the first one that is exclusively used to operate via computer instructions, the router is a CNC masterpiece that revolutionized the industry.

It is the first-ever created that uses a computer as the main interaction hub between humans and machines. Routers are built to create some amazing stuff. For example, routers differ in the amount of axis. Each axis cuts in one dimension. The most common router is a three-axis Cartesian coordinate, which effectively cuts any wood, metal, plastic, etc, in three dimensions.

However, as technology is improved and perfected, there can be found routers with up to four, five, and some with six-axis. They don’t cut in four, five, nor six dimensions, but they are heavily used to instantly produce or cut a complex prototype model and shapes.

There are many uses for this machine, but we’ve singled out the six most popular ones that include:

- Furniture making

- Cabinet making

- Sign Making

- Crafts & Arts

- Mould Making & Prototyping

- Architectural Design uses

If you’re interested in purchasing routers for your business, then make sure to visit elephant-cnc.com.

4. CNC Plasma Cutter

CNC plasma cutters are exactly the same in size as routers, but the only difference is in the way they perform the job.

CNC plasma cutters are huge machines that can perform a large number of tasks, but their primary usage is for cutting wood, metal, or plastic.

If the router had a big spinning wheel in the middle that is used to cut the material, then the plasma cutter uses a plasma torch mounted on top of the thing.

We mentioned their use, but we should mention that they are quite limited in terms of how much they can cut. If routers were capable of cutting with six axes, then CNC plasma cutters can mostly cut in two dimensions. They aren’t built to perform complex cuttings, but they are super effective at what they do.

There are two types of plasma cutters out there, CNC machines that operate through a computer, and handheld ones that a person can directly cut with.

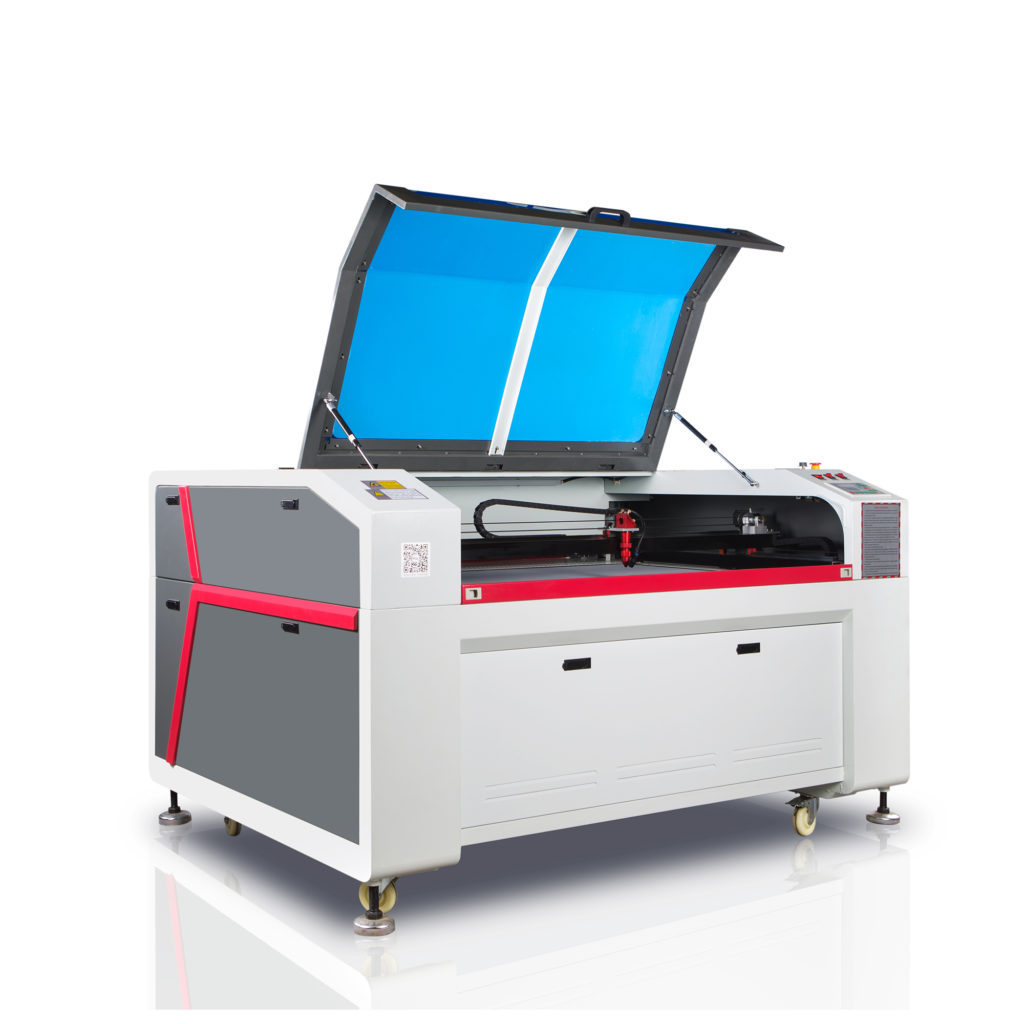

5. CNC Laser Cutter

An extremely precise piece of machinery, CNC laser cutters are some of the most common types of CNCs that use computer controls to do the cutting.

Like the rest of the contraptions on this list, a laser cutter is extremely good at doing its job. But unlike the plasma cutter or the router, a laser cutter uses a laser to perform the cutting. You can say that this is the most powerful means to cut any piece of material that you give the machine.

It is super effective at precisely cutting wood, foam, concrete, metals, etc.

However, the laser can be manually set to a specific depth of cutting. For example, you could have the laser set to do a full cutting, or engrave a specific material.

Truthfully speaking, laser cutters are heavily used for engraving. Like the plasma one, this machine performs the cutting through the set of instructions you’ve to give it through the computer. Every laser cutter comes with software that needs installing, and every large industry has a different use for this machine.

One thing’s for certain, laser cutters can come in different sizes and can be used for different things. Since they don’t require a person directly operating it, it makes the job a lot easier, faster, and cheaper. With all that said, these machines are some of the most expensive CNCs in the industry.

But, for high precision, speed, and flexibility, you’d expect to see a return on your investment.

The rest of the CNC bunch is made out of 3D printers and Pick and Place Machines. Both use elements from the router, but also from the laser cutter. The former, unlike the latter, isn’t used to cut materials, but to create ones. The latter, though, gets the name since it effectively picks small electrical components and places them on circuit boards.