Protecting your eyes at work requires the right gear. Standard eyewear does not provide enough protection in hazardous environments. Prescription safety glasses offer clear vision and defense against dust, debris, and chemical exposure. Choosing the right pair ensures both comfort and security.

Work environments determine the best design and features. Construction sites, factories, and laboratories each require different levels of protection. Prescription safety glasses for contractors need durable frames and impact-resistant lenses. Jobs involving chemicals or flying particles demand side shields or anti-fog coatings. Fit and coverage must align with workplace hazards to prevent accidents.

Comfort plays a key role in daily wear. Adjustable nose pads, lightweight materials, and secure temple grips improve usability. Lenses with protective coatings extend durability and reduce glare. Meeting safety standards guarantees reliable performance. Selecting the right pair keeps vision sharp and prevents long-term damage.

Assessing Workplace Hazards

Every job comes with specific risks that affect eye safety. Construction sites expose workers to dust, debris, and flying objects. Laboratories pose chemical splash hazards. Factories present risks from sparks and machinery. Identifying workplace hazards helps in selecting the right prescription safety glasses.

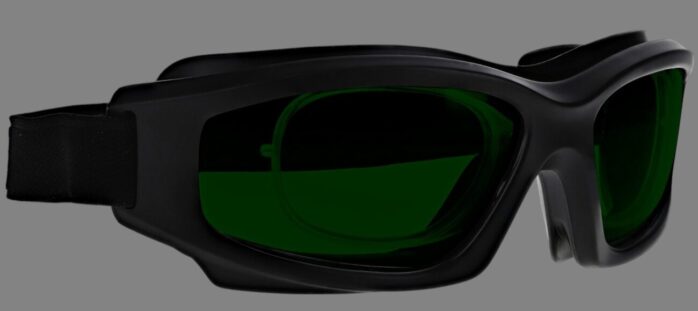

Some environments require impact resistance, while others need chemical protection. Work involving bright lights or welding requires specialized lens coatings. Indoor and outdoor workspaces demand different lens tints for optimal visibility. Fogging can obstruct vision in humid conditions, making anti-fog coatings necessary. Understanding potential dangers allows workers to choose glasses that provide full protection.

Employers often set safety requirements based on industry regulations. Workers should ensure that their eyewear meets these standards. Failing to assess risks can lead to injuries that compromise both health and productivity. Choosing appropriate protection ensures safety and clear vision throughout the workday.

Frame Durability and Design

Frames must withstand daily wear without breaking under pressure. Impact resistance remains essential for high-risk jobs. Polycarbonate frames offer lightweight durability, making them a strong option. Metal frames provide stability but may lack flexibility. Wraparound designs protect against side impacts, while adjustable nose pads improve comfort. Some work conditions require non-conductive frames to prevent electrical hazards. Flexibility allows frames to absorb impact without snapping under stress.

Comfort influences wearability, preventing distractions during work. Prescription safety glasses with reinforced hinges last longer in tough environments. Selecting frames suited to workplace conditions prevents frequent replacements. An improper frame choice can lead to discomfort or inadequate protection. The right frame enhances safety without sacrificing vision clarity. Investing in high-quality frames reduces the risk of accidents and ensures long-term usability.

Lens Materials and Coatings

Lenses determine clarity, durability, and protection. Polycarbonate lenses offer impact resistance and lightweight comfort. Trivex lenses provide similar benefits with enhanced optical clarity. Glass lenses resist scratches but weigh more than synthetic alternatives. Safety coatings improve lens performance in demanding environments. Anti-scratch coatings extend lens lifespan, preventing wear from debris. Anti-fog treatments ensure clear vision in humid or temperature-changing conditions.

UV protection coatings block harmful rays, reducing eye strain outdoors. Polarized lenses reduce glare, improving visibility in bright conditions. Tinted lenses enhance contrast, making details easier to see in specific lighting. Choosing the right material and coatings maximizes both protection and comfort. Prescription safety glasses must support job requirements without compromising vision. The right combination prevents frequent replacements and improves long-term performance.

Prescription Safety Glasses for Contractors

Construction workers need durable eyewear that protects against debris, dust, and impact. Prescription safety glasses for contractors require shatterproof lenses and strong frames. Polycarbonate materials resist high-velocity impacts, preventing eye injuries. Side shields offer extra protection against flying particles on active job sites. Anti-fog coatings prevent condensation during physically demanding work. Dust-resistant coatings keep lenses clear in dry environments.

Adjustable frames improve comfort for long shifts. Wraparound styles ensure full coverage without obstructing peripheral vision. Lens tints help workers adapt to changing lighting conditions. Meeting ANSI safety standards guarantees proper protection on construction sites. Poor-quality eyewear can lead to vision issues, discomfort, or injury.

Choosing prescription safety glasses designed for demanding environments ensures long-lasting performance. Contractors should prioritize comfort, fit, and durability when selecting protective eyewear.

Ensuring Proper Fit and Comfort

Ill-fitting glasses cause discomfort and reduce effectiveness. Secure frames prevent slipping during movement. Adjustable nose pads and flexible temples improve stability. Lightweight materials reduce pressure on the face, making extended wear easier. A proper fit eliminates gaps that allow dust or debris to enter. Wraparound designs enhance side protection without limiting visibility.

Glasses should remain secure without causing pressure points. Loose frames shift easily, increasing accident risks in hazardous environments. Tight frames cause headaches and discomfort, leading to decreased wear time. Soft padding on nose bridges enhances comfort for all-day use. Prescription safety glasses must stay in place during physical tasks. Choosing a comfortable, well-fitted pair ensures reliable protection throughout the workday.

Safety Standards and Certifications

Safety eyewear must meet industry standards for protection. ANSI Z87.1 certification guarantees impact resistance. OSHA regulations outline workplace eyewear requirements for various industries. EN166 certification applies to European safety standards. Some jobs require additional protection against chemicals, heat, or electrical hazards. Proper labeling indicates compliance with relevant safety regulations.

Employers often mandate specific certifications based on job risks. High-risk industries, including construction and manufacturing, demand strict compliance. Glasses without proper certification may not offer adequate protection. Testing ensures durability against impact, chemical exposure, and optical clarity issues. Meeting safety standards prevents injuries that could lead to vision damage. Investing in certified eyewear guarantees long-term reliability and security.

Customization Options for Specific Needs

Specialized coatings and lens colors improve performance in different environments. Blue light filtering reduces eye strain for digital tasks. Photochromic lenses adjust to changing light conditions. Anti-glare coatings enhance visibility for nighttime or bright settings. Prescription strength must match individual vision needs. Side shields offer extra protection against airborne hazards. Some models allow interchangeable lenses for adaptability. Prescription safety glasses with custom tints help in varying work conditions. Frameless designs provide a lightweight feel for extended wear. Strap attachments keep glasses secure during active movement. Customization enhances comfort, clarity, and protection. Selecting personalized features ensures maximum efficiency at work.

Maintenance and Longevity

Proper care extends eyewear lifespan. Cleaning lenses with microfiber cloths prevents scratches. Avoiding harsh chemicals protects coatings. Storing glasses in a protective case reduces accidental damage. Checking screws and hinges prevents loose fittings. Regular inspections detect wear before it compromises safety. Replacing worn-out nose pads improves comfort. Anti-fog sprays maintain clear vision in humid environments. Proper storage keeps lenses free of dust and debris. Prescription safety glasses must stay in optimal condition for reliable protection. Routine maintenance prevents costly replacements and enhances performance.

Cost vs. Quality Considerations

Higher-quality safety glasses offer long-term value. Cheap models may lack durability, leading to frequent replacements. Impact-resistant lenses prevent costly accidents. Investing in high-grade materials reduces breakage risks. Frames with reinforced hinges last longer under demanding conditions. Anti-scratch coatings prevent early wear, extending usability. Prescription accuracy ensures clear vision without distortion. Budget options may lack essential safety features. Evaluating costs against benefits helps in making a smart purchase. Choosing reliable eyewear prevents unnecessary expenses on repairs or replacements.

Last Words

Selecting the right pair requires assessing workplace hazards and comfort needs. Frames must fit securely without causing strain. Lenses should match environmental conditions, offering clarity and protection. Safety certifications ensure compliance with workplace regulations. Custom features enhance usability and performance. Comparing different models helps in finding the best balance of cost and durability. Prescription safety glasses must provide clear vision and full protection. Choosing wisely ensures long-term safety and comfort at work.