O-rings and gaskets are essential components in various industries. They are commonly used to create a seal between two surfaces and prevent leaks in applications, such as engines, pumps, and valves. Although they are both designed for the same purpose, there are some critical differences between them.

O-rings and gaskets are usually made of different sizes and materials, which are to be chosen carefully depending on their intended applications in specific industries. This article will explore how these two sealant solutions are used by discussing their functionalities in these five sectors: automotive, aerospace, construction, food and beverage, and medical.

What Are O-rings And Gaskets?

O-rings and gaskets are two main types of seals that are commonly used in industrial applications. These sealants are typically made of elastomers. Elastomers are polymeric materials that can recover their original shape after being stretched or deformed. O-rings and gaskets are often used interchangeably; however, they are two different items.

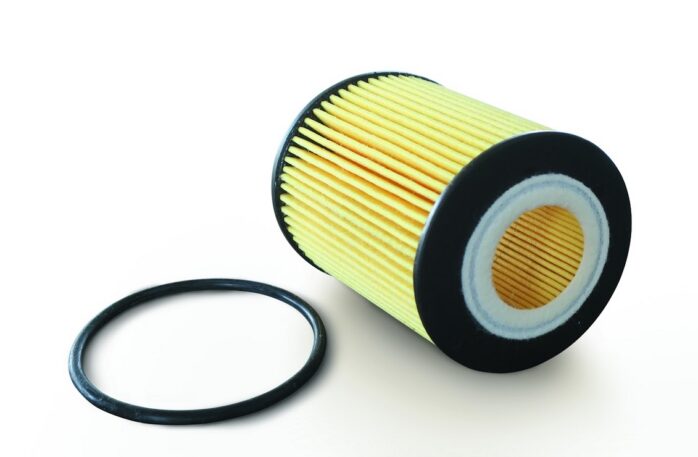

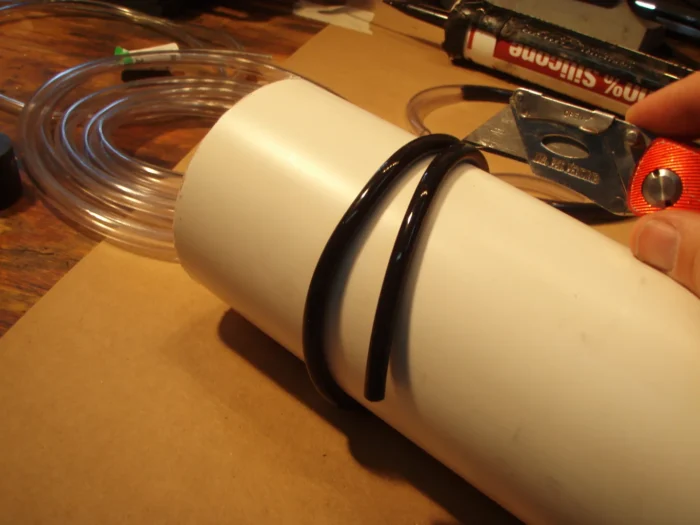

An o ring seal is a donut-shaped seal placed in a groove on one of the mating surfaces. These are used to prevent leaks in applications where a dynamic seal is required, which means that the seal is designed to move in relative motion with the two joined surfaces.

On the other hand, a gasket is a seal between two surfaces and held in place by bolts or other fasteners. Typically, gaskets are used in applications where a static seal is required, meaning that the seal is designed to remain in place despite relative motion between two surfaces. Although gaskets are mostly made of elastomers, they can also be made of other materials, such as steel and asbestos.

How Are O-rings And Gaskets Used?

O-rings and gaskets are often used in applications with extreme temperatures or harsh chemicals. They are used in these diverse applications since they are available in various sizes and durometers, a measure of hardness, each of which has its advantages and drawbacks. The material, size, and durometer are selected according to the specific application and conditions to which the seal will be exposed.

The most common elastomeric materials used for this and gaskets are nitrile rubber, silicone, and fluoroelastomers, but they can be custom-made to match a specific purpose. With that being said, here are some common ways gaskets are used in different industries.

-

The Automotive Industry

O-rings and gaskets are vital components in the automotive industry. These sealants protect sensitive components from corrosion and contamination by sealing numerous parts and systems, such as engine seals, transmission seals, and differential seals. These are used in fuel lines, water pump housings, oil pans, transmission cases, and other gas-filled components to seal and prevent leakages. On the other hand, gaskets seal the engine head, exhaust manifolds, and gearboxes and prevent oil and coolant from leaking.

Since they reduce friction, O-rings and gaskets can improve the overall efficiency of automotive systems. These two items are necessary to achieve the vehicle’s optimal operation and must be replaced regularly to keep the vehicle running smoothly. Typically, O-rings and gaskets in automobiles are replaced every two to four years or when they show signs of wear.

-

The Aerospace Industry

In the aerospace industry, O-rings and gaskets are used to seal fluids and gases in various applications, such as aircraft engines, fuel systems, and hydraulic and pneumatic systems. In contrast, these are used in aviation engines to seal the cylinders and prevent fluid or gas leakage. These sealants are used to seal joints and prevent leaks in these systems, thus ensuring that the aircraft operate safely and efficiently.

-

The Construction Industry

O-rings and gaskets are often used in construction to seal joints in machinery and other equipment. Similarly, they are useful in electrical systems to seal electrical connections and seal joints in construction structures.

O-rings are also commonly used in plumbing applications, such as pipes and fittings requiring a watertight seal. Rubber O-rings are the most common type of O-ring used in plumbing, as they are relatively inexpensive and have excellent water resistance. In addition, silicone Furthermore, due to its resilience to heat and chemicals, silicone O-rings are frequently used in plumbing applications.

-

The Medical Industry

In the medical industry, O-rings and gaskets are used in various ways. For example, they seal off the opening of a blood vessel or body cavity and create a barrier between different body tissues. In addition, gaskets can be used to prevent fluids from leaking out of a medical device implanted into the body.

O-rings and gaskets are also used in the medical industry to create a seal between two pieces of medical equipment that are incompatible with each other, thus preventing fluids from leaking out of these devices. For instance, O-rings can be used to create a seal between a catheter and a syringe. This is because the catheter is made of a different material than the syringe, and the two materials can expand and contract at different rates. As a result, the O-ring prevents the two pieces of equipment from becoming detached.

-

The Food And Beverage Industry

O-rings and gaskets have a range of applications in the food and beverage business. O-rings are commonly used to seal connections between pipes, valves, and other components in food and beverage processing equipment. Moreover, to avoid carbon dioxide leakage in a beverage can, gaskets are used to seal connections between two flat surfaces, such as the lid of a food container and the container itself.

O-rings and gaskets for food and beverage applications are available in various materials, including food-grade silicone. The food and beverage industry are very cautious regarding these products since even minor leaks can cause contamination of food and beverages that can lead to health problems and wasted products.

Tips To Keep In Mind

- O-rings and gaskets are available from several manufacturers. Some of them specialize in O-rings or gaskets for specific applications, while others offer a wide array of O-rings and gaskets for general use.

- When selecting O-rings and gaskets, it’s essential to consider the specific application since they must be compatible with the materials they will be sealing. Lastly, you must also ensure that they’re suitable with the temperatures and chemicals they will be exposed to.

Conclusion

Due to their outstanding sealing characteristics, O-rings and gaskets are widely used in various industrial applications. They are also available from different manufacturers in various materials, sizes, and durometers which must be selected based on the application. So, if you’re looking for a way to prevent leaks, O-rings and gaskets are the way to go. Contact a seal expert today to learn more about how O-rings and gaskets can be used for your specific applications.