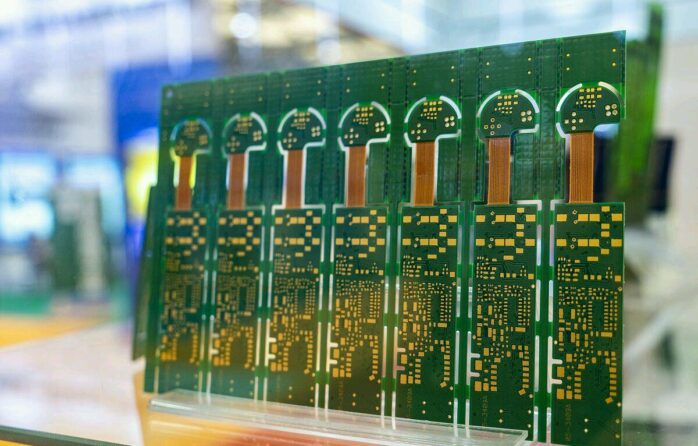

From smartphones to computers, all the way to traffic lights, PCBs – printed circuit boards – can be found everywhere. They’re most commonly manufactured from fiberglass or composite epoxy and they also contain conductive pathways that allow manufacturers to connect different electronic parts together.

However, since there has been an increase in PCBA manufacturers in recent years, it might be a bit daunting for you to find one that suits your needs. To help you through the choosing process, we’ve compiled a list of the top six things you must do and consider before choosing a PCBA manufacturer that you’ll work with:

1. It Might Be Easier to Make a List First

One of the first things that you might consider doing is making a list of all the potential manufacturers that you could work with. Although this isn’t necessary, it’ll make the entire process easier for you, mostly because you’ll be able to go through our list of tips easily, and in the end, you’ll be left with some of the best companies that you can hire. Hence, you should browse through several websites and write down the names of the companies.

2. Read What Other People Had to Say About The Companies

Once you’re done making the list, you should read the reviews and testimonials left by previous clients, mostly because this will help you quickly narrow down your list of potential candidates. Of course, if there are more negative than positive experiences, you should simply scratch that company from your list and move on to the next one. Keep in mind, that if you want the reviews to be completely honest, you should read them on independent sites since they tend to be more transparent there.

3. Experience is Crucial When Making a Decision

No matter what you need printed circuit boards, ensuring that the manufacturer you hire has experience is one of the most important things that you could do. Not only will this prevent you from spending money on PCBs that, for instance, don’t work, but it’ll also save you a lot of time since you won’t have to search for another company and then wait for them to complete manufacturing the boards.

Hence, you should learn how long they’ve been operating in the industry, however, there is one thing more important than this – learning whether or not the company strives to implement new things, as well as to adapt their business to suit the changing trends in the industry. For instance, PCBA manufacturer such as pcbasic.com has been operating for more than 15 years, thus, it’s quite clear that they’ve been providing high-quality products to their customers.

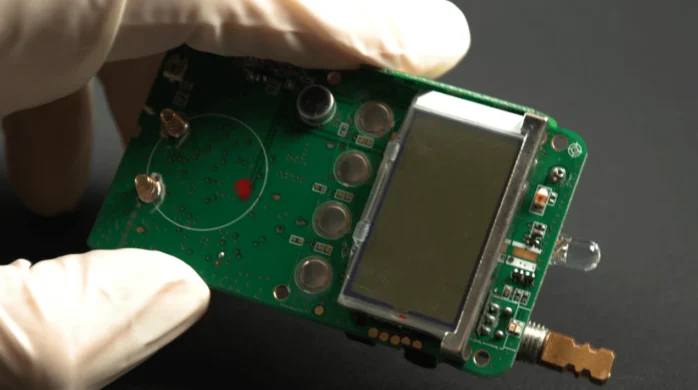

4. Their Products Must Be High-Quality And Long Lasting

As mentioned, choosing the wrong company will result in lost time and funds, which is something that you’ll definitely want to avoid. Because of this, you should keep in mind that quality is always crucial when it comes to choosing a PCBA manufacturer, thus, don’t neglect to examine what they offer to their clients. To help you determine whether or not a product is high-quality, there are several factors that you can look for.

For starters, the design has to be high-density and the lines – pathways – also have to be high-speed. Second, the conductivity needs to be good since otherwise, you might have issues when you connect the PCB to the product you’re working on. Lastly, the boards have to be durable since this is what ensures that they can be used for a really long time. Thus, make sure that you check what each company offers.

5. The Manufacturer Needs to Comply With The Industry Standards

If there is one thing that you must remember from this list, it’s the fact that all PCB manufacturers must comply with the industry standards, including the IPC, ISO, and UL standards. For instance, the UL fire-resistance certification is incredibly important when looking for a PCB manufacturer, mostly because this will ensure that your products won’t get damaged simply because you’ve connected them to a printed circuit board.

The company you opt for working with should provide certificates with each shipment and more importantly, they should have a segment on their website where you can see what certifications they have. If a company doesn’t provide certifications, you might want to scratch it off the list you’ve made, mostly because this might mean that they aren’t completely transparent with their clients, thus, it might not be wise to order boards from them.

6. The Manufacturing Cost is an Important Factor to Consider

Now, the first thing that you should know is that the manufacturing cost will vary from one company to the next and it’ll also depend on the design, size, and of course, quality of the PCB. Things such as choosing a different base material or choosing a different substance for the soldering mask will make your expenses higher, thus, you should think carefully about what you require for the project you’re working on.

Comparing the prices and services you can get is also quite important and it can help you narrow down your list, hence, don’t forget to compare everything. By doing so, you’ll be able to narrow down your list, however, you’ll also be able to choose an organization that provides the best PCBs for the price you’re willing to pay. All of this means that you also must consider your budget and how much you’re willing to spend.

Conclusion

No matter why you’re looking for a PCBA manufacturer, choosing one can be time-consuming and daunting, especially since there are so many options available on the market. However, y following the tips we’ve mentioned above, you won’t only make the entire process quicker, but you’ll also ensure that you choose a suitable company.

By now, it’s pretty clear what you’ll have to do in order to choose a PCBA manufacturer, thus, you shouldn’t lose any more of your free time. Instead, head back to the beginning of our article, and start with the first thing we’ve mentioned – which is making a list of all the potential companies you can work with.