The world of controlled testing environments is a fascinating one. Often hidden from the public eye, these chambers play a pivotal role in ensuring the reliability and longevity of a myriad of products.

In this blog post, we explore the nuances of environmental test chambers. Whether you’re a scientist, an engineer, or simply curious about how things are tested before they reach your hands, this guide will shed light on a topic you may have never considered before.

What’s Their Essence?

Environmental test chambers are integral to understanding the performance of materials and products in different environments. This section delves into the heart of what they are and why they’re crucial.

Their Primary Function

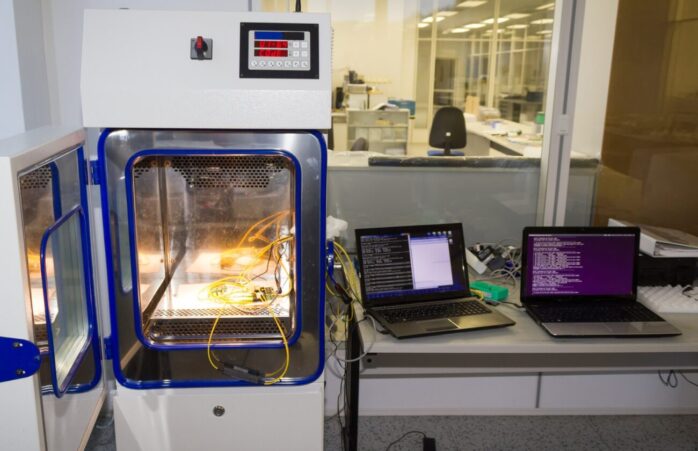

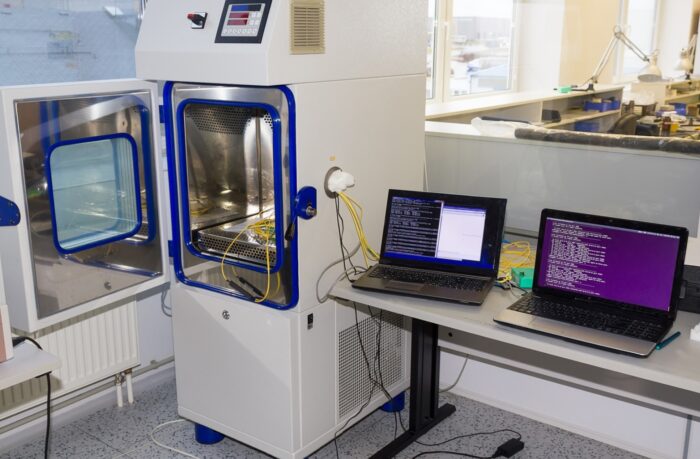

An environmental test chamber is a space where conditions such as temperature, humidity, pressure, radiation, and other environmental factors can be precisely controlled. These chambers are essential for industries that need to test their products under different conditions to ensure their durability and functionality.

The primary function of these chambers is to recreate extreme environments on Earth, from the scorching deserts to the freezing polar regions, and sometimes even beyond our planet. By exposing products to these conditions, manufacturers can identify potential weaknesses and improve their designs.

Industries That Rely On Them

From aerospace to pharmaceuticals, environmental test chambers serve a myriad of industries. The automobile industry, for instance, utilizes these chambers to ascertain vehicle components’ resistance to different weather conditions.

Similarly, pharmaceutical companies use these chambers to study the impact of various environmental conditions on drugs, ensuring that they remain potent and safe for consumption irrespective of where they’re stored. The versatility of these chambers makes them indispensable to various sectors.

Types of Test Chambers

With a diverse range of applications, it’s no surprise that there’s an array of environmental test chambers available. Let’s explore some of the most common types.

Climatic or Temperature

Climatic chambers, as the name suggests, primarily control humidity and temperature. These are perhaps the most common types of environmental chambers, used in industries ranging from electronics to food.

A product’s integrity, especially those with delicate electronic components, can be compromised in extreme temperatures. By simulating these conditions, companies can make necessary modifications to ensure product stability.

Additionally, humidity control is essential for products susceptible to mold, corrosion, or other moisture-induced damage.

Thermal Shock Chambers

These chambers are designed to test the resilience of products when exposed to sudden extreme temperature variations. Within moments, the chamber can go from icy cold to blisteringly hot, subjecting the test object to rapid temperature changes.

Electronics, metals, and ceramics are commonly tested in thermal shock chambers. A sudden change in temperature can cause materials to contract or expand, leading to potential failures.

By identifying these weak points, manufacturers can enhance the reliability of their products.

What are their Components?

The success of an environmental test chamber lies in its components. A closer look at its primary parts reveals the precision and innovation at play.

Control Systems

The heart of any environmental test chamber is its control system. This component allows users to set specific parameters for the test, be it temperature, humidity, or any other factor.

Modern chambers often come equipped with digital touch interfaces and programmable logic controllers (PLCs) for added precision.

Additionally, advanced control systems offer features like data logging, remote monitoring, and alarms. These functionalities not only ensure the accuracy of tests but also provide safety mechanisms to prevent any catastrophic failures.

Airflow Systems

Airflow plays a pivotal role in ensuring uniform conditions throughout the chamber. Fans, ducts, and vents are meticulously designed to offer an even distribution of the controlled environment.

Different tests might require varied airflow patterns, and this is where the design’s brilliance shines. Whether it’s a gentle breeze for subtle temperature variations or a more vigorous flow for rigorous tests, the airflow systems in these chambers are tailored to meet specific requirements.

Key Features and Specifications

Choosing an environmental test chamber isn’t as simple as picking a model off the shelf. The features and specifications vary based on requirements. This section dives into the elements you should be considering.

Size and Capacity

Environmental test chambers come in a range of sizes, from small bench-top units to walk-in chambers that can accommodate large equipment or batches of products. The size you need largely depends on the scale of your tests.

For startups or academic institutions, smaller units might suffice. However, large-scale manufacturing units or research facilities often opt for larger chambers to run multiple tests simultaneously or test larger items.

Range and Stability

The range refers to the span of conditions the chamber can simulate, from the lowest to the highest temperature or humidity. Stability, on the other hand, indicates how consistently the chamber can maintain these conditions.

For instance, if you’re testing an electronic component that’s expected to function in both Arctic and desert environments, you’ll need a chamber with a broad temperature range.

The chamber’s stability ensures that during a test, the conditions remain consistent without sudden, unintended fluctuations.

Testing Protocols

For effective use of an environmental chamber, one must understand the protocols that guide the testing process. This section demystifies the standards and methodologies.

Standardized vs. Custom Protocols

Many industries have standardized testing protocols to ensure consistency and comparability across different products or batches. For example, ISO, ASTM, and IEC set specific guidelines for numerous industries.

However, some unique products or specific research questions might necessitate custom protocols. Here, the onus lies on the tester to define parameters, durations, and conditions that align with the product’s expected usage or the research’s objectives.

Importance of Calibration

Calibration is the process of verifying and adjusting the chamber’s readings to align with a standard. Periodic calibration ensures that the conditions inside the chamber match the settings and readings displayed.

Without regular calibration, a chamber might drift from its set conditions over time. Such drifts can compromise the integrity of the tests, leading to misleading or inaccurate results. Hence, calibration is a critical aspect of the testing protocol.

Safety and Maintenance

While environmental test chambers are built to withstand extreme conditions, they aren’t invincible. This section emphasizes the importance of safety measures and routine maintenance.

Safety Features and Protocols

Most modern environmental test chambers come equipped with a range of safety features. These might include over-temperature protection, alarms for abnormal conditions, or safety shutdowns.

However, apart from built-in features, users must also adhere to safety protocols. This could involve wearing protective gear, ensuring the chamber is used in a well-ventilated space, or adhering to specific operational guidelines.

Routine Maintenance and Checks

To ensure the longevity and consistent performance of an environmental test chamber, regular maintenance is paramount. This involves cleaning, checking for wear and tear, replacing old components, and ensuring that the software, if any, is updated.

Maintenance not only prolongs the chamber’s life but also ensures the accuracy of tests. Overlooking this critical aspect can lead to equipment malfunctions and compromised test results.

Conclusion

Environmental test chambers represent a remarkable intersection of science, engineering, and innovation. These environments provide an invaluable lens through which we can predict and understand the behavior of myriad products under diverse conditions.

Whether it’s ensuring the reliability of a satellite that will orbit Earth or guaranteeing that a simple household appliance functions optimally in various climates, these chambers play a pivotal role.