Almost every part of our life, at the workplace and home, is powered by electricity. We wouldn’t be without the labor-saving equipment in the kitchens, such as washing machines, microwaves, heaters, and teapots.

The TV, camera, or audio system is there in the sitting room, where we may utilize a work computer, a cell phone, or a photocopier. Plastics enable advancement by rendering electronics safer, lightweight, better appealing, silent, more resilient, and environmentally sustainable.

Plastics are beneficial in the realm of electronics because of their excellent insulating properties. Plastics, when properly changed, may conduct electricity, making them more flexible and opening up a plethora of uses beyond shielding.

These unrivaled features, along with design and production processes, typically give cost-effective alternatives, justifying plastics’ domination in the electrical & mechanical industries. The need for machined components that may be utilized in the production of electrical and electronic equipment has been expanding at an accelerating rate, as has the electronic industry.

Many companies are recognized for producing and supplying precision-engineered molded components such as high-performance polymers, polymeric molded parts, and industrial components for OEM, among other things. In the electronics sector, these molded components are in high demand.

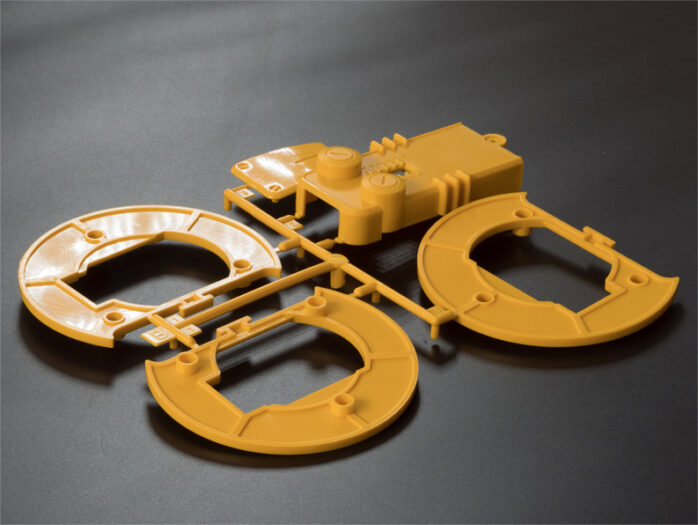

Injection Molded Parts

Plastic is excellent stuff for electronic equipment. It may be made of electrical or non-conductive plastic resin and can be used with waterproof sealing. It’s UV resistant, and it comes in a variety of colors.

It can be used in stiff or elastic systems, and it has functionality beyond metals and other materials. Because plastic is so simple to design and mold, it may help reduce installation costs by including snap-together self-matting pieces that align without extra hooks, rivets, nails, or bolts.

The electronic industry relies on various instruments such as meters, commercial test equipment, detectors, etc. Producers of these parts want components that are very precise and accommodating with tight tolerances and good mechanical in even the most demanding situations.

Components created using two-shot mold processes such as insert molding, micro-molding, miniature molding, and over-molding, among others, are required to satisfy such criteria.

Latest injection molding technologies

Hardware switches and buttons have been phased out as the movement toward compact gadgets continues. Innovative operational interfaces and graphics are taking their place, which can only be accomplished with combined IMD and IML systems.

Micro injection molding and very high molding constraints enable accuracy molding that allows for exceptional quality while building small elements for compact goods as electrical parts shrink in dimension.

Other materials that have conductive qualities can be formed into plastic. Small multi-pronged plugs, unusual pin configurations, and connections are examples.

To lessen the shock and give more flexibility, overmolding can merge new plastic material with already casted or metal pieces. Injection molding electronics goods from Rydtooling.com include temperature control, inkjet printer, computer motherboards and housings, smartphone circuits, and coverings.

What Makes Plastics Invaluable?

Design Freedom

Whatever the designer imagines, plastic can make it happen. They may be any shade — clear, milky, or solid — and any texture – glossy to reduce glare in the workplace, flat for easy cleaning in the kitchens, or non-slip for grips. Plastics have adapted to the ergo dynamic curves that make contemporary tools simple to use and secure.

Reduced Wastage

Because plastic goes into a mold, trimming off surplus material isn’t necessary. The amount of plastic required is predetermined by the mold. Other components frequently require cutting and fitting to get the desired size and form. It is less costly to make since there is less wastage.

We already live in a dirty world, with broken materials accounting for the majority of pollution; thus, if the manufacture of new materials results in less waste, it is a miracle, and the technology must be extended to other sectors as well.

Durable

Plastics are sanitary, durable, and simple to wash and preserve. It doesn’t rust or degrade as metals and other biological things do. They are oily and chemical immune, which is a vital feature for instruments, and they can be made shatterproof. Plastic does not go easily – a common phrase, and now it seems the time to use it for our benefit.

Energy efficient

Plastics account for just 4% of total oil output. It needs less energy and, as a result, less fossil fuel to manufacture than most conventional materials. It lowers the cost of production and purchase while also going green by saving energy.

We are already running out of natural fuels, and it is time we focus on other resources that do not empty our natural reservoirs. Interestingly, plastic is the best option for that. All because of innovative technology, it is turning out to be a blessing in disguise.

Recyclable

Many of the plastic parts in items that have reached the pinnacle of their useful lives can be recycled, giving them a second life and saving energy and raw resources. It is one of the overlooked and underrated qualities that we specifically need to give humanity a second chance.

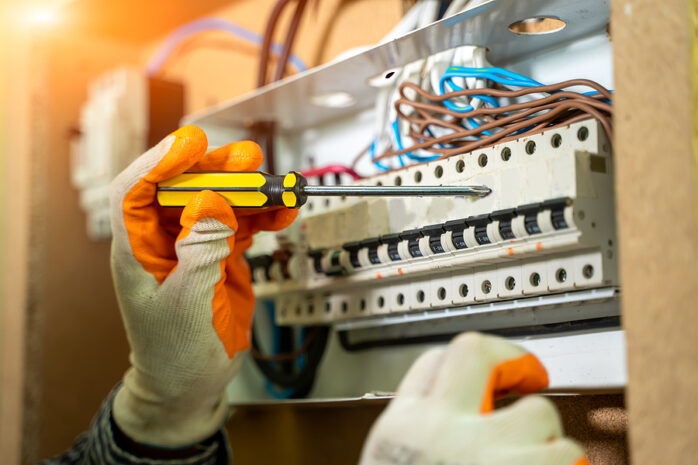

Insulation

Electronics are often fragile and vulnerable to water and severe conditions. Electronic components are protected from hazardous elements by plastic covers. They also serve to protect the consumer by preventing electrical impulses from fleeing.

For this purpose, electric appliances that connect to the wall outlet, such as food processors and hair straighteners, are enclosed in plastics.

Perhaps, this is one of the first benefits that brought plastic into use, and now it is being considered in the last. It is to showcase that plastic has evolved a lot and is on a life-changing journey.

The Parting Words

Over the last centuries, electronics have been the center of attention, yet plastics have enabled them. Plastic has aided the electronic sector in achieving new milestones through components, cabinets, and microprocessor molding.

Electronics would not be manufactured overseas in the same way they are now if not for plastics. Plastics enable electronics to continue to evolve by rendering them more functional and cost-effective.