Almost all the gadgets and electronic devices that are currently available on the market use plastic parts. The material is used across the world, regardless of industry and type of product.

This having been said, plastic is not only important for assembling the finished product that will be placed on the shelves, but also for creating the prototypes and tweaking designs. In other words, all manufacturers need custom plastic components to create new products.

In an age when 3D printing is becoming increasingly affordable and easier to do from home, we’ve come to take plastic for granted, especially when it comes to creating and using precisely designed components.

What is rapid tooling?

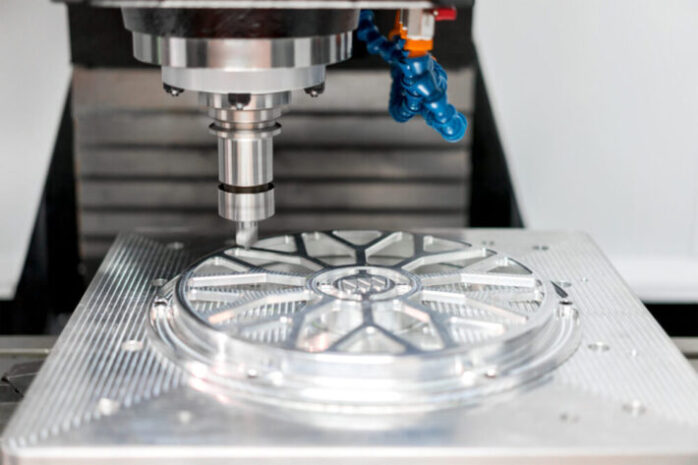

While 3D printers are great if you want to be creative and design decorative pieces that you can display throughout your home, creating plastic components for prototypes is more difficult than it seems. These elements need to have as few seams as possible to offer maximum structural integrity, and this means using injection molding.

The main issue with this technology is the fact that it takes a long time to produce the required components because a new mold must be created every time the specifications of the plastic piece change.

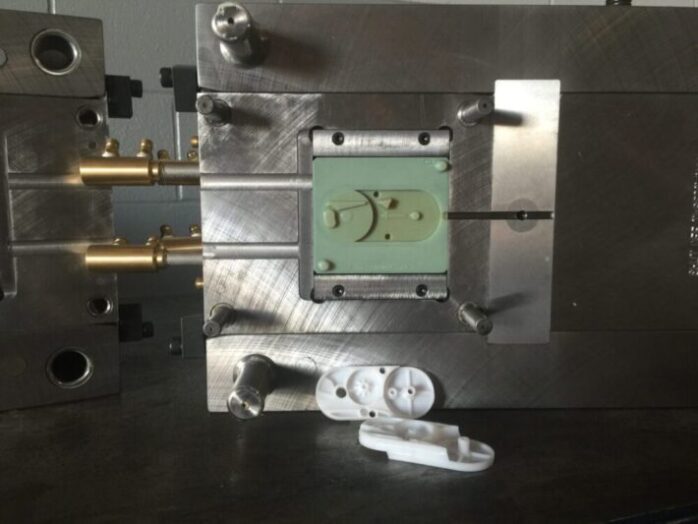

According to NiceRapid, fast tooling, also called soft tooling, refers to a manufacturing process where production is focused mainly on creating a single component, rather than on making several ones that have consistent characteristics. The method is mainly used for prototyping because it only takes a fraction of the time and is considerably more affordable that what production tooling would cost.

What are the advantages of rapid tooling?

From a manufacturing point of view, rapid tooling is faster and much more affordable because it uses silicone molds that are easier to produce than aluminum or steel ones. Although these can only be used for 10-25 times before they deteriorate and become unusable, they can shorten the tooling time it takes to create functional prototypes for products that are currently in development. In other words, rapid tooling is perfect for short batches of components that are needed as fast as possible.

Another great advantage is the fact that the process is extremely cheap, which makes it easier to take small steps in terms of design and structural changes without having to worry about production costs. Overall, rapid tooling makes it easier to try new things or to create small amounts of plastic components for a fraction of the time and price of what would be required for production tooling.

Lastly, depending on the size of the designs and their complexity, a single mold can be used to create several plastic components, which means that rapid tooling can also be used for mass production, to some extent.

What about complex components?

Silicone molds work best with simple designs, however, a bit of human intervention can add more details to the components or shape them so that they follow your specifications. Regardless of this, rapid tooling is, as the name implies, faster than other ways of producing plastic components.

Rapid tooling equipment for home fabrication

Depending on the type of rapid tooling that you choose for your prototypes, it is possible to move the entire production line to your home. However, this can only be done if you have all the required equipment. While the equipment is not particularly expensive, it should be treated as an investment. Depending on the complexity of the project, you may have to print each part separately and assemble them.

For more simple components, you will be able to use home 3D printers to manufacture them. Most of these devices are somewhat slow when compared to industrial 3D printers, but their capabilities will be enough to make 2-3 units each day. This having been said, it is important to keep in mind that the printed components will need further processing in order to smooth out their edges prior to assembling the product.

Generally speaking, there are several ways to set up a rapid tooling production line in your home. One option is to purchase multiple basic 3D printers that would work round-the-clock, leaving you only to assemble the parts. Alternatively, it is also possible to invest in high-quality 3D printers that are able to print several completely separate objects or even entire sets at the same time. These are more expensive, but they can print parts in bulk.

As far as the production line is concerned, if your product has components that can be printed at the same time, using a single printing head, and then separated, you will be able to cut manufacturing time in half.

How to save money when using rapid tooling?

Rapid tooling is one of the most affordable ways to prototype a product, however, the method can also be used to cut the costs of production in half. Starting with the design process where you can use soft tooling to create a mockup that will help you find the ideal form-factor of your product, to the manufacturing process that can be done using 3D printing, all aspects of creating and making a product can be done from home.

Although some form of mold-making may be required for certain parts of the product, it is possible to eliminate the need for third-party rapid tooling by purchasing one or more 3D printers. These will allow you to both save money as well as time by taking the shipping time for certain components out of the equation.

Furthermore, by using rapid tooling from home you will be able to make modifications to the assembly line on the fly, without having to spend time sending new specifications to a third party rapid tooling company. It will also be easier to tweak the production process to use fewer materials or to try different ones.