Working in construction or in the glazing industry has always considered to be quite dangerous, but thanks to glazing robots, we are able to ease a bit of pressure from such workers. Instead of having to rely on basic lifting equipment such as ropes, pulleys, and cords, we can now use these robots that use a vacuum to lift any kind of material. Some machines can lift anything from huge granite plates to all kinds of vehicles. This is a much safer and more efficient alternative than any other solution.

Many companies have started purchasing these little robots so their employees can become a lot more efficient when it comes to setting up glass windows or whatever it is that your company does that is related to lifting a heavy glass. With the use of this kind of vacuum, you won’t have to worry about ruined goods anymore. Of course, there is still the chance of human error since the machines are controlled by a human hand.

So, if you are looking for a way to reduce the risk of your workers being hurt during the job, you should definitely consider investing in a glazing robot.

1. What is glazing?

Well, if you are reading this article then you probably already know what the phrase stands for. It comes from the English language from the 13th century. It is meant to describe a part of a wall or a window that is made from glass. The people who handle this kind of work are referred to as glaziers.

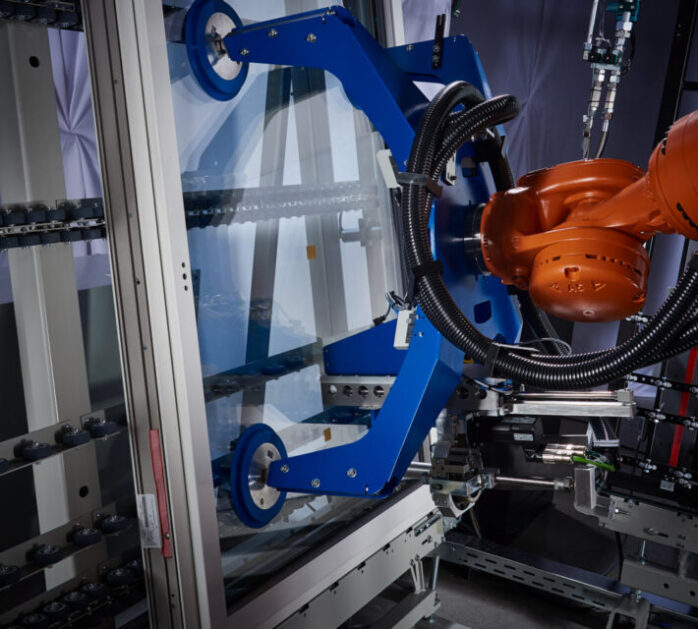

2. So, what are these robots?

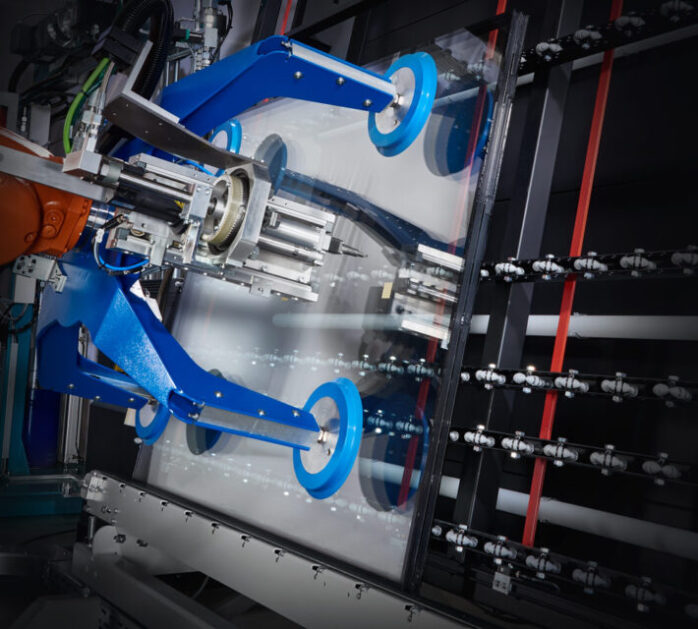

Well, it is quite simple. Take the idea of a mechanical robot and the work of a glazier and you get a machine that can handle heavy pieces of glass. It can do the entire lifting part of the glazing process that a glazier would have to go through. With this kind of piece of equipment, the glazier won’t have to worry about dropping these heavy pieces of material or about his/her back ever again.

It is usually used during the finalization of the installation when assembling the frame of the window. This is a much safer variant than having other people to support it while you are installing the frame or having to prop it on something which can be very risky. And most employees probably don’t want to break anything because it will probably get cut from their paychecks.

3. A safer alternative

Having the ability to prevent any kind of mild or life-threatening injury from your employees is one of the biggest reasons why companies have started purchasing them. It allows glaziers to maneuver the large panes in any position and to any location, in any way they want. No one will be required to do the heavy lifting anymore which significantly reduces the number of injuries your company faces throughout the year.

By reducing the amounts of accidents that occur throughout the year, you will also be effectively increasing your yearly revenues since you will not have to pay multiple insurance costs that can range anywhere from a few hundred to several thousand dollars. The fewer accidents you face, the less you have to worry about insurance expenses and costs. If you have decided that it is time to reduce the amount of risk your workers have to face on their job, check out cpslift.com.

4. Efficiency

Every single business in this world constantly aims to be more productive. The more efficiently you work, the more your clients will be pleased. This usually results in recurring customers and word to mouth advertising.

So, investing in such a robot is not just about the safety of your workers, but you will also improve their efficiency. Even the most productive employee in your company will get surpassed by your slowest workers if they have access to this kind of machine. They will be able to break your company’s record of installed window panels in a day. Yes, it is actually that useful. In other words, you will be so efficient in your work that you will be able to take on a lot more contracts which will ultimately lead to a lot more profit. And who doesn’t want more profits, right? The price of these machines will pay themselves in quite a short time.

Some of these glazing robots have a reach of around 10 feet. And some can even go even higher than that. How does this help with your work? Well, instead of having to use people to carry heavy glass panels through the inside of a building or through the scaffolding, you can just use these lifters to raise the materials to the needed floor. Sure, you could bring in a crane to the construction site, but that is a much more expensive option considering that it is just a one-time installation. Not only is it expensive, but it also takes a lot of time to set it up. Some areas won’t even have the required free space to add a crane.

You can also take the SL 400 Sky Lifter as an example since it has the option to be attached to a front loader. So, the maximum height will be dictated by the front loader and not by the lifter. This certain model can also handle around 400kg of weight which is more than enough to handle even the heaviest panels of glass.

5. How to choose the right glazing robot?

Naturally, making such an investment is not as easy as it sounds. Sure, it does seem like it has very attractive benefits and no disadvantages, but you still have to justify such a big cut from your budget. So, before you make the purchase you will need to do extensive research on the subject.

To help you with your research and decision we should mention the most notable brands in this industry. If you are looking for most famous companies you should consider either SmartLift or Winlet. Other manufacturers are Oscar and Geko which are also quite reliable. All of these companies will probably offer dozens of different models, so make sure that you pick the right one.