One of the greatest technical innovations of the modern age is certainly 3d modeling. 3d modeling has changed trends not only in design but also in the areas of sales, marketing and many others. Old methods such as the hit and trial method have contributed to greater effectiveness and efficiency. There is certainly room for even greater progress in this area, but for now, this form of modeling has saved huge amounts of money.

This form of modeling gives space to the 3d artist to manage certain points with the help of specific software. These points are located in the virtual world and are popularly called vertices. With their help, shapes and objects are created. All this takes place with the help of polygons, which are usually in the shape of triangles. This is the perfect technique for an artist to bring his idea to life. However, things are not as simple as the theory suggests. Big companies spend millions of dollars on quality software, high-end computers, and worthy 3d artists to produce their films.

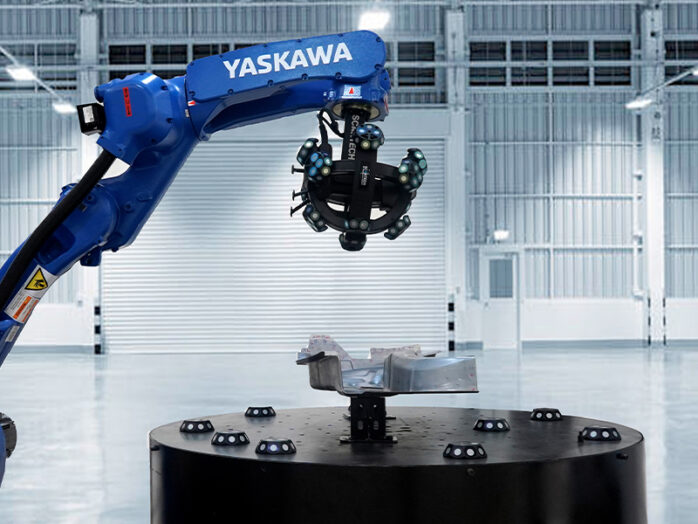

Additional 3d equipment can be used to create incredibly precise 3d models. In this sense, something that is necessary if we want quality is a 3d scanner, says 3d-scantech.com. Clay and drawings fall into the shadows when it comes to 3d scanning. By scanning, you get a picture of the object from each side, and that’s exactly how you can observe it: from every possible side. This high technology is very important when it comes to design. If you are not sure how 3d scanning technology can improve product design, stay with us and find out.

1. Reverse engineering

This is one of the most important and useful options that 3D scanning allows us to do. The 3d scanner collects information about the object that is in the center of the scan with incredible accuracy. It is now easier, faster and more efficient than ever to have incredibly accurate data on an object so that even designers could continue to deal with it. Identical parts of a particular product can be produced more easily than ever. In addition, printing a life-size object is easier than ever.

2. Goodbye trial testing

Many prototypes have not passed the trial tests or have not even reached this stage because of their high costs. Now we can say goodbye to long and expensive trial tests because 3d scanning came on the scene. Very easily, this method can identify even the smallest problem. This saves a lot in the production of defective goods. Mass production of a certain product would be almost meaningless without 3d scanning. Save time and a large amount of money. In the virtual world, you assemble and check before everything is sent and approved for production or assembly. Quite logical. We have information on outcomes in advance, so there is no need for pointless production and expensive trial testing. Everything is on the screen.

3. Architecture is never faster

The working day of an architect until the 3rd scan and after it is not nearly the same. In the past, it took a lot of time, precision, and drawing to design even the smallest space, not to mention larger projects such as the whole building. Today, this process is much faster, but not only that, and much more precise than before. With the help of 3d scanning, the whole building we want to model can be replicated. It is clear to everyone that this saves time for both architects and their clients. In addition to saving time, you have accurate information that can be used later for modeling and changes.

4. Monitoring product development

Many manufacturers would be grateful if they knew these 3d scans before they invested all their resources in the production or assembly of a new product. How many companies went bankrupt after the product was placed and failed. Now you have something to help you save both money and time. 3d scanning allows you to get an insight into how your product will work and whether it will be accepted on the market or not in time, before investing. When you join analysts and technicians in this, then you can be sure that your product will be a complete hit with maximum efficiency.

5. Creativity, efficiency, and effectiveness

Creating 3d models from the very beginning requires a lot of time and resources. With the help of scanning in an hour, you have a 3d model that you can work on. The savings in effort and time here are more than obvious and you will have the model needed for further processing in a very short time.

In addition to efficiency and effectiveness, we must not forget the creativity that 3d scanning allows you. This is indispensable when it comes to brand development. You can choose whether to scan an existing product and make changes or create something completely new. All the creativity you have here can come to the fore. As we said, e3 modeling creates 3d artists, free and creative.

3d is truly a marvel of modern technology and many industries have already become dependent on it. Among them are the aviation industry, the automotive industry, medicine, and many others. However, without 3d scanning, 3d modeling would not be so simple, fast, and economical. Therefore, it is almost impossible to observe these two segments separately. If you want to learn more about 3d scanning, we suggest you visit here.

However, don’t forget, although all this sounds extremely simple and easy, it is very difficult for us laymen to learn something like this. Even beginners who have a great interest in this field are not easy to master all the skills of 3d modeling and 3d scanning. This is not one in a series of games that will interest you for a short time after which it will be forgotten. This is a serious business, the software used in 3d modeling is very complicated and everything is not cheap. However, if you recognize in your self-consciousness for something like this, supported by a great desire to learn in this field, why not. And once you master this method, there are no limits for you. Your creativity and opportunities will not be hindered. After all, this is one of the best technologies that modern times have brought.