A 3d printer uses versatile 3D print materials such as resin, metal powder, wax, plastic, etc., depending on its type. Talking about FDM printers, they generally use thermoplastics, a material that melts at high temperatures and solidifies after it cools down.

Are you having an FDM printer and thinking about which 3D print material would be ideal? Then, be worry-free, as we will tell you about the most beneficial 3D filaments and their exciting properties for your perfect choice.

PLA: Natural and biodegradable

PLA filament is the most common material among 3D printer material options used for FDM Printing due to its easy processing and smooth surface finish. This material is ideal for beginners and consumers as it needs low temperature to process, lacks the need for a heated bed, and has a low cost per kg.

PLA filament has excellent UV light resistance and is also biodegradable. However, you should keep in mind that it has low humidity resistance, making it difficult to glue. In addition, these thermoplastic filaments can bear up to 50 degrees of temperature. Beyond that, it can soften and lose its shape. This filament is generally used for 3D printing prototypes and other plastic materials.

ABS: Strong and Durable

If you want higher toughness and greater temperature resistance than PLA, then ABS printer material (acrylonitrile butadiene styrene) is a good choice. Although ABS is affected by various acids and solvents regarding its chemical resistance, you can turn it into an advantage by post-processing it with acetone vapors for a glossy, smooth surface finished product.

It is tough and durable relative to PLA and can resist many wears and tears. You can use it for making end-use parts from the filament 3D printers. Relatively, it is slightly harder to print than PLA and would require a heated bed and closed FDM printer to avoid shrinkage and issues such as warping or cracking.

PET-G: Highly Durable and Flexible filaments

PET is a soft polymer, which can be readily called an intermediate between PLA and ABS. This material has a high resistance to chemicals and humidity. In addition, this 3D printing material is safe for contact with eatables and possesses tremendous abrasion resistivity.

Users generally praise PET-G for its strength. It is a durable and strong plastic suitable for making high-impact resistance parts, food packaging, and decorative stuff. However, it is difficult to take out from the printing bed. Furthermore, you would need to be careful in managing its shrinkage issue.

ASA: Superior Aesthetics

If you want better mechanical properties and superior aesthetics relative to ABS, then this is an ideal choice. ASA print material is an all-purpose plastic which is strongest among PET, ABS and PLA.

You can use it to make durable and tough materials that resist water, high temperature and UV rays, such as automotive external printed parts or marine applications. However, it also got some drawbacks such as warping and dangerous fumes that can rise during 3D printing, because of styrene.

TPU: Most flexible filaments.

In the world of 3D printing materials, TPU wins the award for the most flexibility. This thermoplastic polyurethane is highly resistant to abrasions and wear and has high elongation. These plastics possess high adhesion among their layers that aids them to be ideal for different applications related to coating and protection. You can use it in automotive parts, sports goods, medical devices, footwear, etc.

These plastics have high strength and come in various hardness. The toughest one is the easiest for 3D printing. However, it is not that cost-effective and has a limited life before which you should utilize.

PVA: Soluble support material

As the multi-material printing system came to life, So did the support materials came into being. Polyvinyl alcohol is a perfect choice when 3D printing complex geometrical parts that are difficult to extract, so it has the integrity of structural support.

This 3D printing material is water-soluble, and you should keep it in a dry place to print your support equipment with this suitable material.

PA (Nylon): Tough and Flexible

FDM printers use this popular 3D printer material due to its excellent mechanical properties. It can be called the best non-flexible filament. The high tensile strength and high-temperature resistance make it suitable for the aerospace industry, strong printed parts, and typically for rapid prototyping.

However, you may face the issue of moisture absorption from air, so you should always keep it in air-tight tolerances. On the other hand, layer adhesion can be an issue too.

Composite materials: Higher resistance with ease.

FDM material also works with composite materials, a mixture of polymers for better physical properties, such as tough PLA or PLA plus, which has higher impact resistance and an easy printing process.

The component materials are also made by combining nylon or plastics with carbon fiber to create the lightweight and printed solid parts.

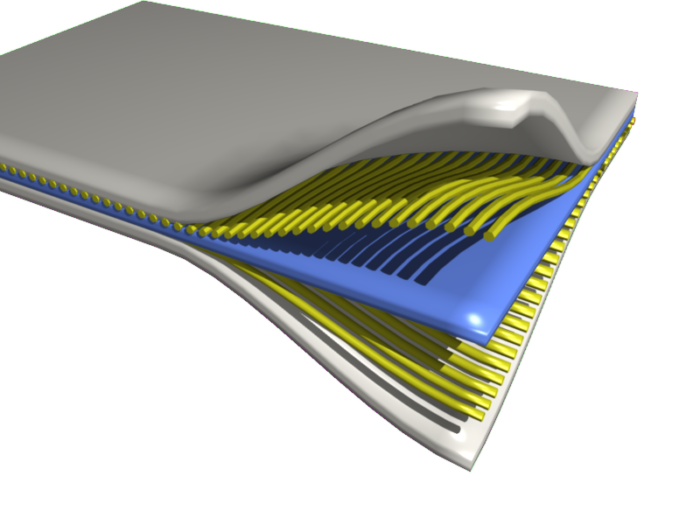

Fiber-filled materials: More strength & stiffness

With the latest developments, industries require more fatigue resistance to 3D printing materials. This resulted in materials made of carbon fiber and glass. A commonly used material is polypropene, which has the chemical resistivity of PP, but mechanical strength is provided through glass fiber.

By 3D printing with fiber-filled filaments, you can make lightweight, durable materials with fibers that prevent shrinking. You can use this carbon fiber filament to make fragile parts. However, they give quite a tough time to nozzles and may clog your Filament printer’s nozzle often.

Metals

Metals are also a rising technology in FDM printing. It has attracted many industries, and professional FDM printers are coping with it readily. These 3D printing materials comprise metal powder and binder polymers. However, before printing, you would need to process it by removing the binders and direct metal laser sintering during the printing process.

This technology is commonly used to produce metal parts and for manufacturing steel. Compared to CNC and casting methods, it creates low-cost metal parts. Moreover, you can post-process it by polishing, welding, or milling to shape it effectively.

Conclusion

Choosing the best 3D printing material for your FDM printer can be tricky, affecting your final product. To choose your ideal filament, you should first clearly sort out your needs and then follow the properties and applications of these top 3D print materials to get the best one for completing your job promptly.