Music is all around us, whether it be listening in the car on your way to work or accompanying some wind-down time at home, it’s an integral part of what makes us human and with the progression of technology comes new ways to listen. Gone are the days of picking a record and placing on the turntable, carefully placing the needle, and replacing the vinyl when it’s finished. We have an entire world of music at our fingertips via a device that sits in our pockets, not only does it make music more accessible for the average joe, but it gives a platform for every musician trying to pave their way in the industry. One of the biggest benefits we have is being able to listen to music on the move, you couldn’t take a vinyl player with you on your travels but know there are plenty of ways to get your fix so let’s take a look at the new ways in which you can listen to music whilst traveling.

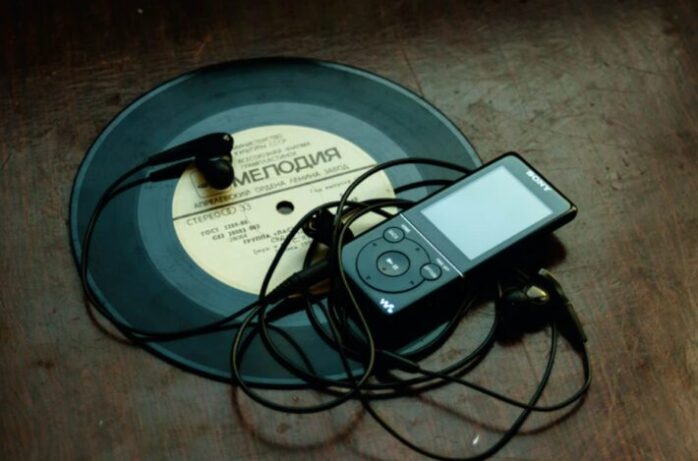

MP3 Devices

Something that could be classed as a little out of date but still something worth looking at is an mp3 device, these enable you to store owned music on a portable device, some even the size of a bottle cap. The benefit of these devices that still trumps the more modern streaming services is you can put anything on there that you might not find elsewhere. Anything that’s converted into an mp3 file can be stored and listened to wherever you are, this means with certain applications you can turn video files into something you can listen to without watching the video. Often is the case where I find a song on video sites such as YouTube that I love but can’t find the same as an mp3 file. 10 years ago this was something that had no fix and you’d end up having to visit the site to listen, but with the development of technology, if you click here, you can now use a youtube downloader to convert the file into an mp3 and listen wherever you please. There’s no better feeling than being able to listen to your favorite version of a song on the go and it’s now easier than ever. The other benefit is being able to store as an mp4 file as well as an mp3, meaning you can watch your favorite music videos whilst your device is offline. A brilliant way of re-living your old music loves in a modern way.

Streaming Services

These hit the market with the original streaming service, Napster, in 2001 and began a movement that would revolutionize music for the masses. You pay a set fee each month and have access to the services extensive library wherever you are, these often include millions of songs, and more often than not you’ll find what you’re looking for. Some bands/artists have exclusive deals with certain streaming sites so doing a bit of research into what’s on offer before choosing your service is advised.

Following Napster came Spotify in 2008 and it further revolutionized the industry, offering more than just an album, they brought live sets and special offerings to the table, and artists were able to provide music in a new way. This way of streaming took off and competitors started to arise, the most notable to challenge Spotify was Apple Music which came to us in 2015 and put up a fierce rivalry by bringing something else to the table, radio. I know what you’re thinking, radio’s been around for years, but not in this way, Apple Music had dedicated radio shows to certain styles of music 24/7 and offered special content that hadn’t been seen before. National radio DJs were changing alliances to get a piece of the action and something incredible was born. Still to this day, Spotify and Apple Music battle it out as the top streaming services and give the listener both individual and incredible content. Something to note as well with these services is that you’re able to download music to your device for when you don’t have any mobile data or access to wifi, meaning you can literally listen wherever, whenever.

Unsigned Music

If you’re someone that likes to go to local gigs and discover upcoming artists then doing this whilst traveling may prove to be difficult, especially if you’re unable to find a music venue. This is where apps such as Soundcloud come in handy, a completely open platform for anyone and everyone to upload their music for the public to listen to. A brilliant way of getting your local gig fix whilst on the move, there have been artists signed through this platform so you can still discover your new favorite local band. The types of artists that are provided on platforms that cater to artists with a smaller audience have the additional benefit of containing a wide variety of genres. You’ll be introduced to those who have been practicing music for decades, wondering how they have not been discovered yet. Or you will find artists who are just starting to experiment with music production, from any combination of alternative and indie music you’ll find something that suits just about everyone here. By listening to artists that haven’t been signed you’re also contributing to their building their audience and if it’s someone that you especially enjoy listening to, hopefully, they will end up getting found.

Music is something we should all have a connection with, it’s emotive and brings us happiness. You may not have found music you love just yet but try and stay connected, chart music isn’t the only sound out there so delve further into the history books and give new music a chance. The development of technology means we can constantly be listening to music, no matter where we are and that’s something really special. Especially when it provides such a large opportunity to artists who might otherwise not have a voice. Never be left in silence again!