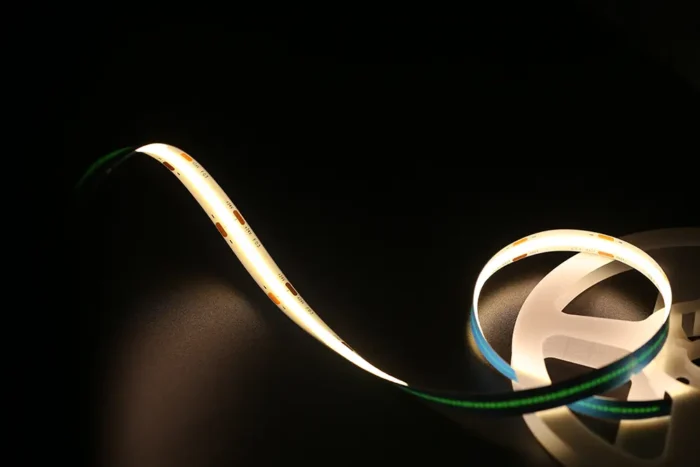

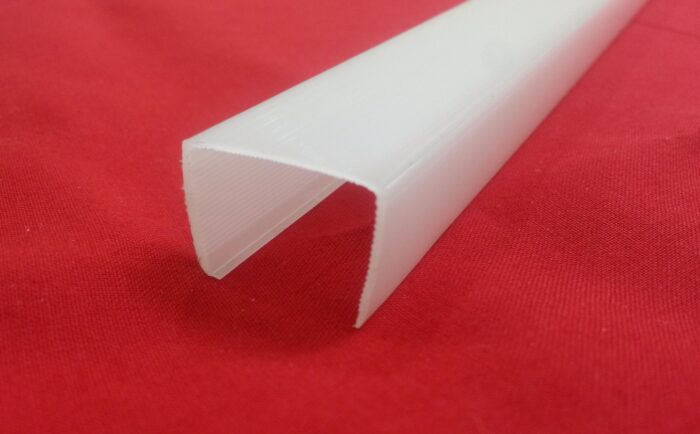

The LED Strip Diffusers are covers or lenses that soften and diffuse the lighting emitted from LED Strips. It helps to reduce glare and create a more uniform and pleasant lighting effect. It also protects the LED Lights from dust, moisture, and damage. It always works with Aluminum LED Channels. They come in various shapes and materials, such as PC, PMMA(acrylic), or silicone. They are commonly used in applications where more diffused and ambient lighting is desired, such as home decor, retail displays, hospitals, restaurants, shopping malls, architectural lighting designs, etc. Today, let’s check their differences and what PMMA vs PC diffusers are.

PMMA, called acrylic or plexiglass, is known for its transparency, impact resistance, and weatherability. The PC is an abbreviation for polycarbonate and is valued for its high impact strength, heat resistance, and optical clarity. These two favored materials are commonly utilized in the manufacturing of an LED Strip Diffuser

PMMA advantages and disadvantages:

1) Less impact resistance than PC

2) More resistant against evenly distributed loads then PC

3) Less likely to scratch

4) Will not yellow after time

5) Better clarity, and Acrylic can be restored to optical clarity by polishing

PC advantages and disadvantages:

1) Impact/chip resistance is much higher than acrylic

2) More likely to scratch

3) Substantially more expensive

4) Used for more industry applications

5) Bulletproof when thick enough

6) More bendable under normal temperature

7) Yellow over time due to ultraviolet rays

8) Easier to cut to any size

9) Poorer clarity, diffuses light

PMMA is often chosen for its excellent optical clarity and scratch resistance, making it popular for applications such as windows, displays, and lighting fixtures. On the other hand, the PC is preferred for its superior impact and heat resistance. It is ideal for applications that require durability and toughness, such as safety goggles, helmets, and automotive components.

Environmental and Health Considerations

When selecting materials for LED Strip Diffusers, it’s crucial to consider their environmental footprint and health implications. PMMA and PC differ in their recyclability and the chemicals involved in their production. PMMA is more easily recycled than PC but may release toxic substances if improperly disposed of. PC, while highly durable, involves more complex recycling processes and can release bisphenol A (BPA) under certain conditions, raising health concerns. Manufacturers are increasingly seeking eco-friendly alternatives and production methods to mitigate these issues, aiming for materials that are both safe and sustainable, minimizing harmful byproducts and ensuring products are disposed of or recycled in an environmentally responsible manner.

Cost Comparison

The cost of LED Strip Diffusers made from PMMA and PC varies significantly, influenced by factors such as material quality, manufacturing processes, and market demand. PMMA is generally more affordable, making it an attractive option for budget-conscious projects without compromising too much on quality. On the other hand, PC’s superior durability and heat resistance justify its higher price point, especially in applications where long-term reliability and performance under challenging conditions are paramount. When comparing costs, it’s essential to consider not just the initial investment but also the potential long-term savings from reduced maintenance and replacement needs.

Thermal Properties

The thermal properties of PMMA and PC play a pivotal role in their suitability for various applications. PMMA can withstand temperatures up to 80-95°C but may deform or crack under extreme heat, limiting its use in high-temperature environments. PC, in contrast, excels in thermal resistance, withstanding temperatures up to 120-130°C, making it ideal for applications exposed to high temperatures or direct sunlight. This superior thermal stability of PC ensures longevity and reliability in demanding conditions, although it may come at a higher cost and with certain limitations in terms of optical clarity.

Maintenance and Longevity

Maintenance and longevity are critical factors in the choice between PMMA and PC for LED Strip Diffusers. PMMA, being less susceptible to scratches and maintaining clarity over time, requires minimal maintenance, primarily regular cleaning to prevent dust accumulation. Its susceptibility to cracking, however, may shorten its lifespan in high-impact environments. PC’s robustness against impact and flexibility make it a durable choice, but its tendency to yellow and scratch over time necessitates additional care, such as UV protective coatings and careful handling during cleaning to preserve its appearance and functionality.

Installation and Compatibility

The ease of installation and compatibility with LED strip lighting systems are essential considerations for both PMMA and PC diffusers. PMMA’s rigidity and brittleness require precise cutting and handling during installation to avoid cracking, but its lightweight nature facilitates easy mounting. PC’s flexibility and high impact resistance allow for more straightforward manipulation and fitting, even in curved or irregular spaces, making it a versatile option for various design requirements. Both materials typically work well with standard aluminum channels and mounting accessories, but ensuring compatibility with the specific dimensions and profiles of the LED strips is crucial for a seamless installation.

Light Transmission Efficiency

Light transmission efficiency is a key characteristic that defines the performance of LED Strip Diffusers. PMMA is renowned for its high optical clarity, transmitting light more efficiently and ensuring bright, consistent lighting without significant loss of intensity. This makes it ideal for applications where maximum brightness and color accuracy are desired. PC, while offering good light diffusion, may slightly reduce light intensity due to its lesser clarity, which can be advantageous in applications requiring softer, more diffused lighting effects. The choice between PMMA and PC in terms of light transmission efficiency depends largely on the desired lighting outcome and application.

Regulatory and Safety Standards

Compliance with regulatory and safety standards is paramount when selecting materials for LED Strip Diffusers. Both PMMA and PC are subject to various regulations and standards that ensure their safety and suitability for use in diverse environments. These standards cover aspects such as flammability, impact resistance, and chemical composition. For instance, materials used in public spaces or in close contact with food must meet stringent health and safety regulations to prevent any risk of contamination or fire hazard. Manufacturers must provide documentation proving compliance with these standards, giving end-users confidence in the safety and reliability of their lighting solutions.

Closing Thoughts

In conclusion, the PMMA Diffusers have better clarity, are less likely to scratch, and do not turn yellow after time. But easy crack. The PC covers are more bendable and have no easy crack. So they are easy to cut. But it has poorer clarity than PMMA and yellows over time due to ultraviolet rays.